Our sensors collect data for AI

Aarup-based company Micro Technic produces a type of electronics that will never be under the Christmas tree. It is the type of electronics that is used in industry and in public space around us, for example in traffic signals. The company’s new business venture is within the world of low power sensors that will take the “Internet of Things” and artificial intelligence to the next level.

Article in Erhverv+ Fyn, 2 May 2019, by Rune Heidtmann

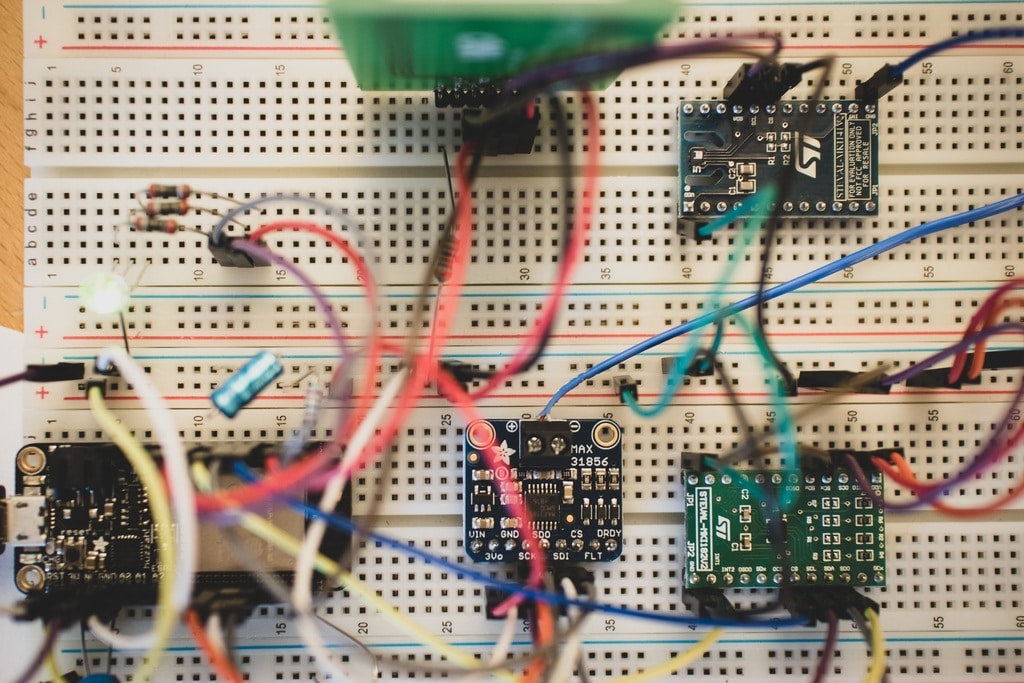

AARUP: The newspaper is visiting Micro Technic in Aarup. CEO Frank Max Laursen shows off his latest “toy” in the company’s electronics manufacturing.

– This machine checks all printed circuit boards of a certain type that we produce. Before, we did it manually. Now we do it with this machine and artificial intelligence that has learned what faulty printed circuit boards look like. When it thinks there is a high probability that a printed circuit board has a flaw, it will be sorted out so that we can repair the flaw, he says.

It may seem like a small thing. But for a production line, this small change means that the company’s production yield on this type of printed circuit board has increased from 67 percent to 90 percent. This will ultimately result in a cost reduction, which will make the company more competitive and more profitable.

AI everywhere

Micro Technic doesn’t just use AI in their own electronics production. The company also produces hardware for the Internet of Things (IoT) like sensor systems that can be placed in many locations to help generate data that artificial intelligence can analyze. Micro Technic also delivers the AI software as a package deal for some customers. As a result, Micro Technic considers itself both a supplier and subcontractor of AI systems. Today, the company’s sensor systems can be found in many places in industry, traffic and agriculture, Frank Max Laursen explains:

– Currently, a big thing in industrial production is “predictive maintenance” as it is called in good contemporary Danish. It is about predicting when your manufacturing machinery needs to be serviced.

– There is a great deal of interest in only servicing machinery when it is necessary. Simply because 25 percent of all errors on a machine happen because it has been serviced. A lot of mistakes can happen during a service check performed by humans, so it is good if you can avoid tinkering with a machine, says Frank Max Laursen.

One system, sold by the company, helps customers avoid doing too much service on their machines:

– For example, we have created a sensor for a Danish system integrator that monitors ball bearings on their large centrifuges. There are many ball bearings in these centrifuges, and they make a certain sound when they rotate. Our sensors can now recognize the sound of ball bearings with no flaws.

– As the bearings get worn out, the sound changes which makes our system raise the alarm and notify you that it’s time to service the machine, says Frank Max Laursen. In the long term, this can save the company huge sums of money since machine break-down can be avoided completely.

– If you know that the machine needs to have its ball bearings changed, then you can plan to pause production for two hours. That is infinitely better than having the machine break down and maybe destroy other things, and having to shut down for several weeks, says the director.

Betting on IoT and data

The sale of IoT systems currently accounts for approximately 20 percent of their revenue, but the company has now entered into a partnership with Martin Brems from Brems & Co., who is a digital transformation consultant. Together, their goal is to increase the sale of IoT solutions to 50 percent within a few years.

– The Internet of Things has enormous potential which we have to tap into more. And with the right amount of effort, we can reach our target. If we get two handfuls of new customers for our IoT-solutions, then we will have reached our goal, says Frank Max Laursen.

An IoT solution from Micro Technic is based on sensors of all shapes and sizes which use a mobile or radio connection to send data to a management system that interprets the data, often using AI.

Weather sensors

– We have, amongst other things, delivered 200 weather sensors that are placed in different locations around Sardinia in Italy. The 200 boxes transmit weather data using a radio connection. The system is important to them because they get heavy rain due to climate change. The system can then notify them when a heavy shower is on its way.

– The special thing about the system is that our sensors are ultra-lower power. There is no 220-volt power plug in nature, so they have to be. They run on battery and solar power. And that is where our strength lies. Not many companies can make sensors that are as low powered as ours. And we have to take advangtage of that, says Frank Max Laursen.

The company has also just delivered a sensor system that will monitor traffic on the motorways of Amsterdam. Once again, this is a solution that is only possible because the sensors don’t require electricity.

– Our sensors register Bluetooth connections from cars and if the same Bluetooth connections are registered around the city, then you can have AI analyze the traffic patterns that emerges from this big data collected by the sensors.

– It helps the local government down there make the most optimal traffic control, says Frank Max Laursen.

Today, the company only sells the hardware, which roughly speaking is a box with a sensor in it. But the question is what the business model around a modern IoT solution should look, says Martin Brems:

– We know that there are many current barriers that make it difficult for people to start using IoT. People think that it is cumbersome to get started with, and they are not really aware of what options they have or what it costs. As a result, Micro Technic is now tasked with informing people and making it simple for them, if they want to be able to sell more sensors.

– For example, if we have to sell a solution to a farmer who monitors his field. Then it won’t do if he has to go out and hire expensive consultants in order for it to work. He needs a system that he, roughly speaking, can stick in the ground and turn on to instantly see on his computer the level of acidity in the soil, if it is sufficiently fertilized or something completely different. It has to be “plug-and-play”, says Martin Brems.

Frank Max Laursen agrees with Martin Brems:

– We want to tailor solutions for people. But the common feature of our solutions has be that anyone is able to set up the system in 10 minutes and be in the midst of seeing live data from system, he says.

One part of the collaboration with Martin Brems will also entail figuring out what the business model of the future should look like:

– In addition to making it as simple and easy as possible for customers to understand the benefits of the sensors and make them see the possibilities for the use of the data they collect – both in the communication and in the actual user experience – it may also be that we need to look at alternative business models.

– Our ongoing analysis of the market and customers, followed by a number of internal workshops, will help to map it out, concludes Martin Brems.

Read the whole article here:

www.e-pages.dk/erhvervsavisenfyn

Read more...

New business models require a new marketing approach

Even though we are truly tired of talking about the Corona Virus and what it has caused – and causes – for our lives, we must admit that the world has changed almost overnight.…

Welcome to Toyota Material Handling as a new customer at Brems og Co.

Toyota Material Handling is number 1 in the world within forklifts. We have the pleasure of having to help with customer insight and initiatives for increased conversion and sales…

The 5-year plan is dead – what now?

You can’t develop your strategy as you usually do in 2021 - and Covid-19 is (unfortunately) a good example of why. Here are 5 suggestions of what you can do instead.

Brems & Co. gets full marks in customer survey

We have a Net Promoter Score of 100. Our customers gave us 4.9 out of 5 in output and project management and Martin Brems received personal and professional praise.

Sustainability has to be the core of COVID-19 recovery

Temperature swings, irresponsible production and economic downturn. Sustainability has been on the agenda for years, but things have changed during the pandemic. Even though novel…

Sustainable marketing strategy for world-famous fitness brand

Most people who have seen the American Netflix series House Of Cards are also familiar with the beautiful handmade wooden rowing machine WaterRower from the company of the same…

Welcome to Megatrade as a new customer at Brems & Co.

For more than 40 years, Megatrade has offered individual customer-specific solutions and services to e.g. hinges and fittings, based on their customers' business. Brems & Co.…

Sports stars and directors throw themselves in the sand at beach volley

Olympic gold winner, bank director, and business owner. These are some of the titles of the members of a networking group that meets early in the morning to play beach volley.…

Brands need to be more human

If one good thing has come from the COVID-19 crisis, it would be that it has given us time and peace to reflect on what it means to be human and part of a family.